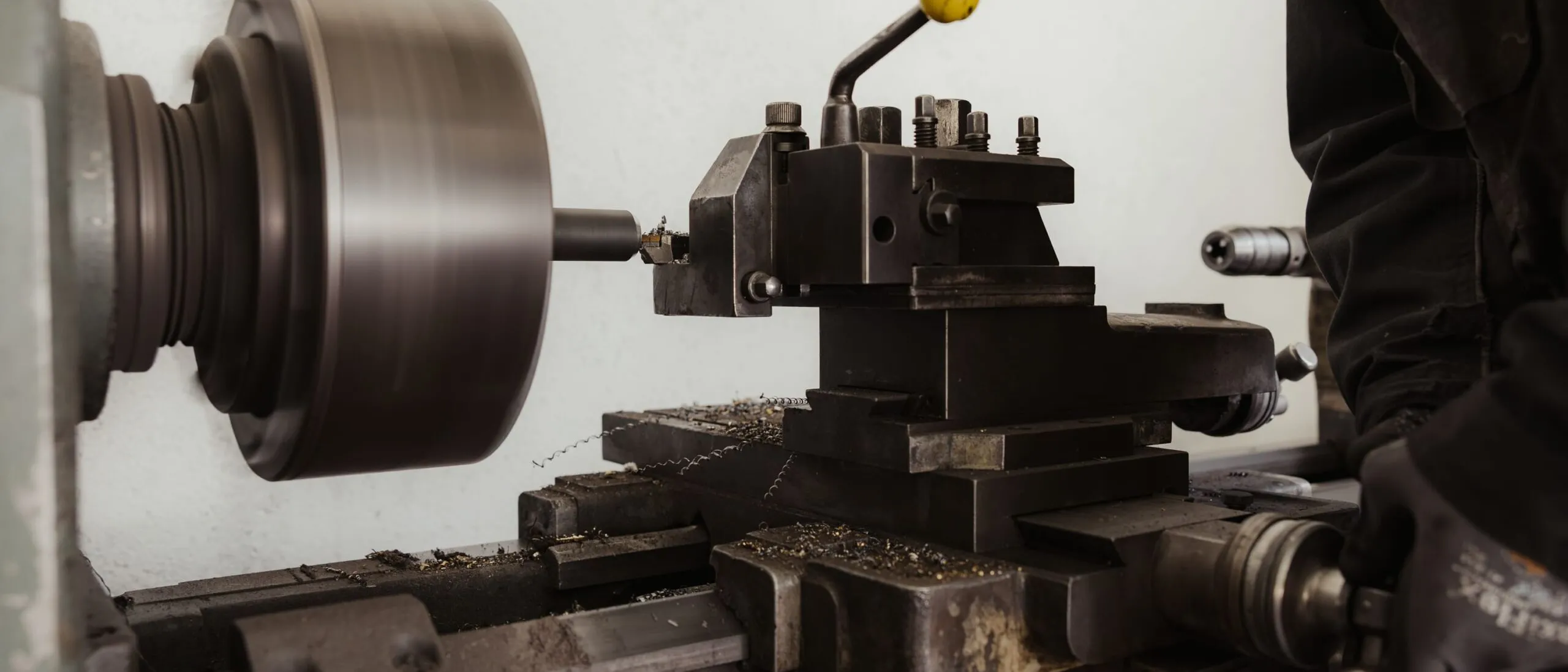

Shaping to within a 0,01 mm accuracy

Turning & milling metals

Components with fine profile

Precision work in rotation

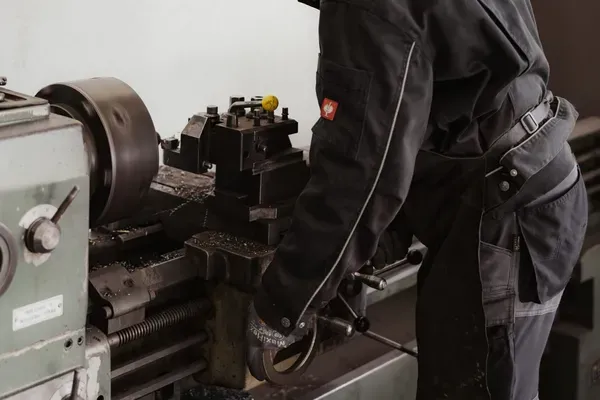

Turning and milling are essential processes in metal cutting, enabling the production of precise round, flat and profiled surfaces. At Isifer, we manufacture components for industry, mechanics and mechanical engineering. Our modern turning workstations enable tight tolerances, high surface quality and reproducible results.

Turning & milling

Top quality individual parts and small series

We use turning and milling to manufacture individual parts, prototypes and small series: Connecting elements, threaded parts, spacer components, rollers, sleeves and components for machines and technical equipment. Materials such as steel, stainless steel, aluminium, brass or copper can be machined efficiently and cut precisely to size. Particularly in the case of moving or precisely fitting parts, turning ensures that designs are ready for assembly and function reliably in the long term.

Our machines

Turning and milling at Isifer

Our turning centres are designed for precision components – from individual turned parts to small series. Perfect for challenging technical applications.

Precision to the finest detail creating overall reliability.

Our metals