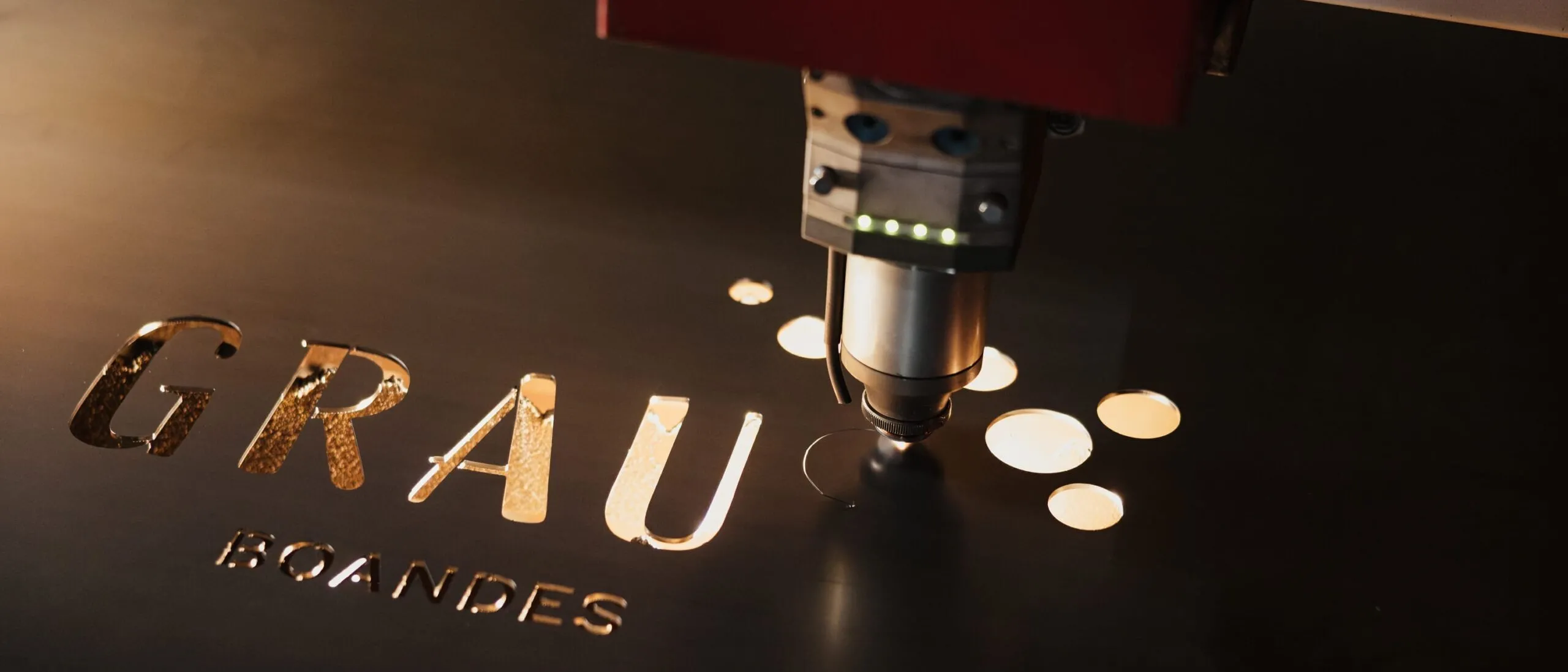

Sharp lines. Strong results.

Metal laser cutting

Cutting quality to the highest level

Innovative laser technology

Laser cutting is one of our core manufacturing processes, which we carry out using both state-of-the-art technology and our many years of experience. The high energy density of the laser beam produces clean, narrow cut joints and precise contours – regardless of whether individual parts, series or complex geometries are involved. Our laser system enables fast processes, reduced reworking and particularly material friendly processing.

Fast, clean, reliable

Precision in metalworking

With our laser cutting system, we process metals of various thicknesses, including black plate and Corten steel up to 20 mm, stainless steel up to 20 mm, zinc and aluminium sheets up to 20 mm, and brass, bronze and copper up to 8 mm. Using optimised processes, we increase efficiency and energy savings, improve reproducibility and guarantee the highest quality results.

Cutting metals

Our laser system

With a size of 3,000 × 1,500 mm, the working area of our laser system offers space for the precise cutting of individual parts and series at high speed – efficiently, cleanly and gently on the material.

Precision without comprise starts with cutting.

Our metals